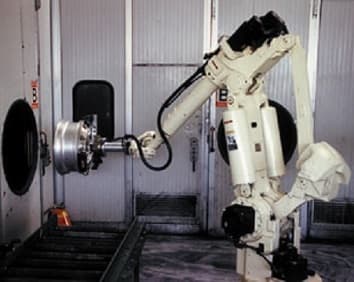

Alcoa® Wheels are forged from one solid block of aluminium

Every wheel starts as a single block of high-strength aluminium alloy.

With an 8,000 tons press, the block is forged into a wheel shape. Once forged, the wheels are heat-treated to maximize overall mechanical strengths.

Precision machining ensures that each wheel is perfectly round. This eliminates any runout in a turning wheel.

The ventilation and mounting holes are drilled.

The last step is the finishing into "Brushed", "LvL ONE®" or "Dura-Bright® EVO".

The Howmet Aerospace forging process aligns the grain flow of aluminium with the shape of the wheel. This process results in wheels with unrivalled forged strength that withstand the most severe tests.

We are so confident in the durability and quality of our wheels, we give a 5 year unlimited mileage warranty.

The best solution for your business

Be the toughest on the road

High strength test results

Reveal that ALCOA® WHEELS are 5 times stronger than steel:

- Forged ALCOA® WHEELS withstand a load of 71,200 kg before deforming

- Steel wheels start to deform already at 13,600 kg

Impact test results

(Japanese JWL test) simulates a vehicle hitting a high curb at 50 km/h. A 910 kg weight is dropped onto the tyre and wheel assembly:

- Steel wheels show excessive rim deformation and air loss

- ALCOA® WHEELS pass the test successfully

Be the lightest on the scale

By switching from steel to aluminium ALCOA® WHEELS you can easily save up to 51% in weight, depending on the wheel size, allowing you to:

- Increase the vehicle's payload

- Reduce your operating costs

- Boost your profitability

Weight Saving Examples

Be the greenest on the planet

Premium quality with low environmental impact

Howmet Aerospace produces ALCOA® WHEELS that have one of the lowest carbon footprints in the industry. We believe that being environmentally conscious is not only good for the planet but also for your business.

ALCOA® WHEELS help reduce CO₂ emissions thanks to their reduced weight. Less fuel consumption means lower costs and a greener fleet.

Ready to upgrade your fleet?

Contact us today to learn more about ALCOA® WHEELS and how they can benefit your business.

Contact Us