Dura-Bright® EVO

Breakthrough Technology

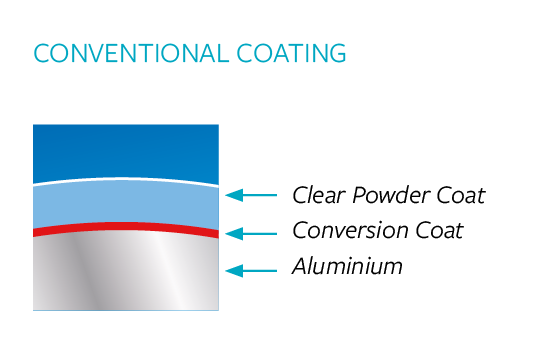

On most aluminium wheels, a coating is typically a layer of baked powder that sits on top of the wheel surface. When scratched, water and salt will penetrate the coating, resulting in corrosion and further deterioration.

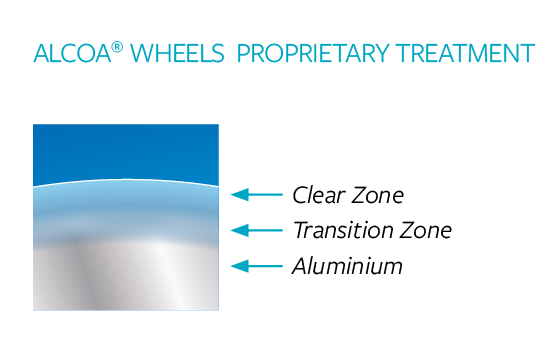

Dura-Bright® ALCOA® WHEELS have a proprietary treatment that penetrates the aluminium and becomes an integral part of the wheel. It will not chip, crack, peel or corrode, like conventional coatings do.

Conventional Coating

Dura-Bright® EVO Treatment

What happens on the road, stays on the road

There is no easier wheel to maintain than a Dura-Bright® wheel. Thanks to the patented surface treatment the wheels will look bright and shiny for years without polishing.

Dura-Bright® wheels can simply be cleaned with a mild detergent or undiluted Dura-Bright® Wheel Wash.

Black and Green

Dura-Bright® EVO wheels are easily recognizable by their black and green Alcoa® Dura-Bright® EVO sticker. Part numbers ending in DB are Dura-Bright® treated.

Dura-Flange®

Additional protection for an even longer service life

ALCOA® WHEELS are available with proprietary Dura-Bright® EVO surface treatment. This treatment allows the wheels to look bright and shiny for years without polishing.

Maintenance is extremely easy thanks to the enhanced protection of the aluminium surface. Regular cleaning with a mild detergent or undiluted Dura-Bright® Wheel Wash will keep the wheels shiny, even after hundreds of washes and thousands of kilometres, reducing maintenance costs.

Part numbers ending in DB are Dura-Bright® treated.

Road tested

Dura-Flange® ALCOA® WHEELS show no signs of rim flange wear after 386,000 km.

Dura-Flange® wheels are the most appropriate for transport where loads are heavy and prone to shifting, causing the tyre bead to rub against the wheel flange, such as:

Heavy haulage and construction

Heavy haulage and construction Tipper applications

Tipper applications Mixer trucks

Mixer trucks Low loader trailers

Low loader trailers

We are so confident in the durability and quality of our wheels, we give a 5 year unlimited mileage warranty.